An ancient house usually needs a lot of wood

A difficult “subject”

Once in a chat, Mr. Duong Dinh Vinh - the owner of Ngu Ha garden and also a famous artisan in the world of crafting Hue's "ruong" houses, said that the most difficult issue for the "ruong" house craftsmen is now wood. The type of wood best used for ruong houses, such as merawan giaza, jack-tree... all are increasingly scarce and expensive.

“Where are the scientists and why don't they help us to research for solutions?” expressed Mr. Vinh.

The conversation between Mr. Vinh and me happened many years ago, but the heart of the artisan crafting "ruong" houses kept ruling my mind. And I raised questions about this whenever there is an opportunity.

However, “the problem” posed by Mr. Vinh was so hard that anybody whom I asked shook their heads. The "ruong" house is beautiful and precious thanks to the wood substance. Using concrete to imitate wood is “too easy” but has no spirit. As for wood, any tree that grows fast for wood exploitation is not good and precious. On the contrary, good and precious trees for wood grow slowly. A good tree ages about 50 - 70 years or a hundred year to be exploited.

While the “problem is difficult”, temples, shrines, "ruong" houses and "roi" houses have been ceaselessly restored and reconstructed. And therefore, demands for types of good wood also increased in a direct proportion.

An answer with full of hope

I am a member of the Organizing Committee of the thirteenth Provincial Children and Youth’s Creativity Contest 2020, which is open to adolescents and children (from 6-19 years of age) to encourage them and create conditions for their competition and innovation on the following fields: learning aids and computer software, environmental friendly products, home appliances and children's toys, and solutions for environment protection and climate change adaptation.

Among this year 141 topics, which is evaluated as the highest number so far, the topic “Automatic wood fortifying system at the cellular level” by Ngo Quoc Huy and Nguyen Tan Tien (Quoc Hoc High School for the Gifted) under the guidance of the teacher Phan Tien Anh caught my attention.

The reason was that the content of the topic was the possibility to “turn” a normal wood into a much harder and more durable wood. More importantly, it could protect the wood from termite and fire. The worse the wood is (that presents the poor quality of the wood), the higher efficiency the fortifying system will achieve.

The method of fortifying, or the so-called method of “stabilizing wood”, was actually not new, however, according to the authors, it was still employed manually with a too complicated, time-consuming, and very expensive but low-efficiency process.

Therefore, it has not been popular with a very small market. Its products were mainly used for manufacturing small equipment such as knife handles, rifle stocks... The authors' “Automatic wood fortifying system at the cellular level” would overcome the above-mentioned shortcomings.

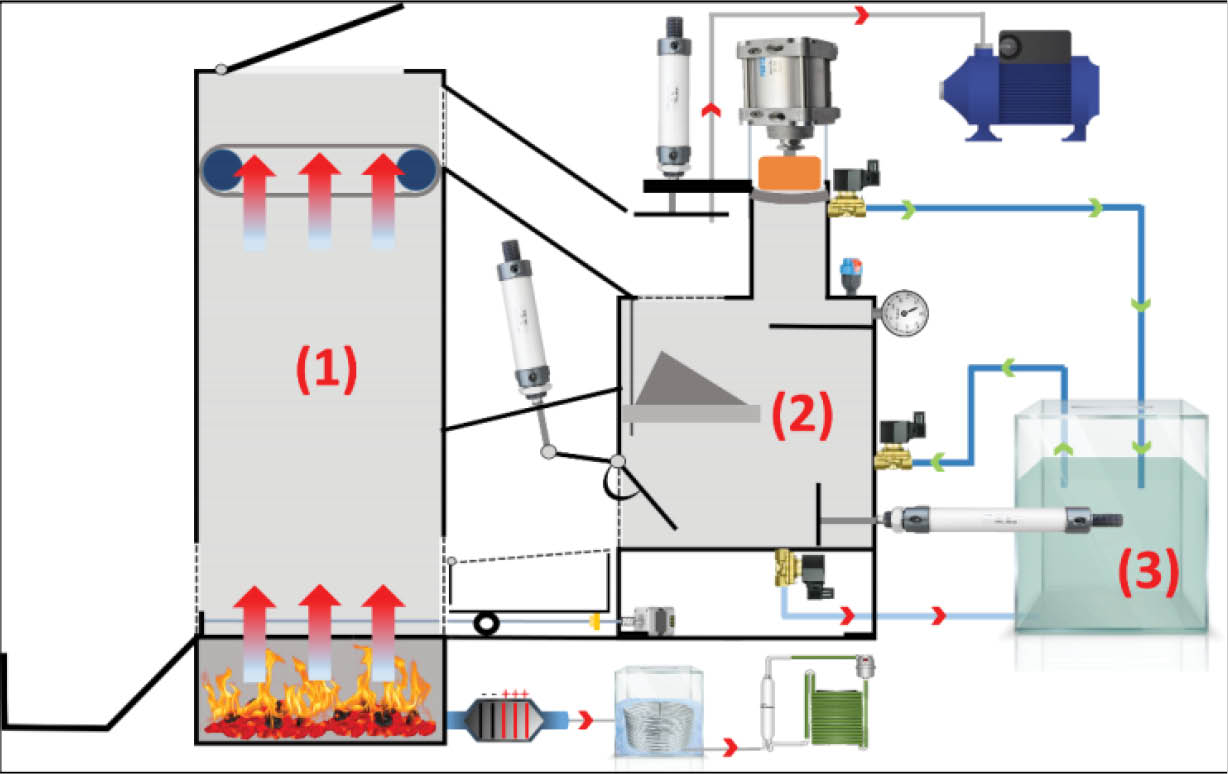

The general structure of the automatic wood fortifying system includes: (1) Heating chamber, (2) Vacuum osmotic pressure chamber, (3) Fortifying substance

The principle of automatic wood fortifying has 4 phases. Phase 1: Drying the wood at a moderate temperature in the Heating chamber (drying chamber) for pressing moisture and air bubbles outside. Phase 2: Taking the wood, that is still hot, into the vacuum environment. The remaining amount of moisture and air bubbles will evaporate to the maximum due to difference in pressures.

Phase 3: Soaking the wood completely in a fortifying substance under high pressure. Strongly pressed by the pressure, the fortifying substance will go into all the void spaces of the wood. Phase 4: After all void spaces in the wood are fully filled with the fortifying substance, the wood will be drying the second time to freeze this substance. The wood cells start linking together with a linkage that is stronger than the previous one dozens of times. This makes the wood harder, more durable and free of moisture, which is a catalysis for the development of termite.

The automation helps shorten the duration of fortifying the wood from several days down to just a few hours thanks to the enhancement of compression pressure. The treating process is also simplified and mitigates any risks. Workers just need to put the wood into the chamber, set the time, then collect the products. This process boosts a superior productivity and always provides a guaranteed product quality.

The experimental result, recognized by the Faculty of Materials Technology - Ho Chi Minh City University of Technology, shows that the automation method is more superior than the manual one in all aspects for the following reasons: The automatic fortifying period is 2.98 times quicker; the amount of fortifying substance is absorbed into the wood is 3.04 times more than the traditional one; the fortified wood processed automatically has a durability of 2.5 times higher than the input wood and 1.8 times higher than the manual wood processing...

With a simple process and the superior productivity, the authors believed that the product price would be much cheaper than the current one. Therefore, this invention would be easily disseminated and widely applied.

A sponsorship is in need

Initiatives and solutions were in place, and experimented. Now, the problem is whether they can be applied into practice to produce in an industrial scale to meet people's demands. Dr. Bui Thang - Permanent Vice Chairman of the provincial Union of Science and Technology Associations (Husta) and Vice Head of the Contest Organizing Committee, shared that attracting the sponsorship to put initiatives into practice is still limited so far.

However, Mr. Thang also revealed that in a few weeks, Husta would host a workshop, with an involvement of many organizations and enterprises, to attract sponsors and investors to support the practical application of the initiatives. That is a good news and a positive move to prevent the youth's initiatives and solutions from being thrown into the drawer after each contest. Instead, they will be given opportunities and favorable conditions for stepping out to the vivid life to meet people's demands. At the same time, this will multiply the youth's inspiration to follow their ceaseless passion for creativity.

Let's get back to the topic “Automatic wood fortifying system at the cellular level” by Ngo Quoc Huy and Nguyen Tan Tien. It is popularly known that repairing and restoring a temple may needs thousands of cubic meters of wood. Then, the hobby for building "ruong" houses and ancient houses are increasingly blossomed in all over the regions, in which each house, depending on their scale, may require from dozens to hundreds of cubic meters of wood. That is not to mention demands of wood for making doors, stairs, tables, cabinets...

These also impoverishes forests. Precious wood become increasingly scarce and is sold with a "dramatically increase" of price. Wood poachers have been tackled but still acted ruthlessly. Then perhaps similar to me, you will pray for theses topics to receive positive support and sponsorship for a quick dissemination and application.

The “Automatic wood fortifying system at the cellular level” by Ngo Quoc Huy and Nguyen Tan Tien (Quoc Hoc High School for the Gifted) under the guidance of the teacher Phan Tien Anh obtained the first prize of the thirteenth Provincial Children and Youth’s Creativity Contest 2020 in the field of “technical solutions for climate change adaptation, environmental protection and economic development".

Story and photos: Hien An